Navigating the Future: Insights from The State of Digital Manufacturing 2024

The state of digital manufacturing survey is here. Find out more how manufacturers are tackling their sales challenges with CPQ

In the quickly changing landscape of manufacturing, adaptation isn’t just a choice—it’s a survival strategy. The fourth edition of “The State of Digital Manufacturing 2024: Unlocking the Power of Digital Transformation,” provides a comprehensive look into the industry’s journey towards resilience and innovation. Through surveys and analysis, we unveil key insights that illuminate the path forward for manufacturers worldwide.

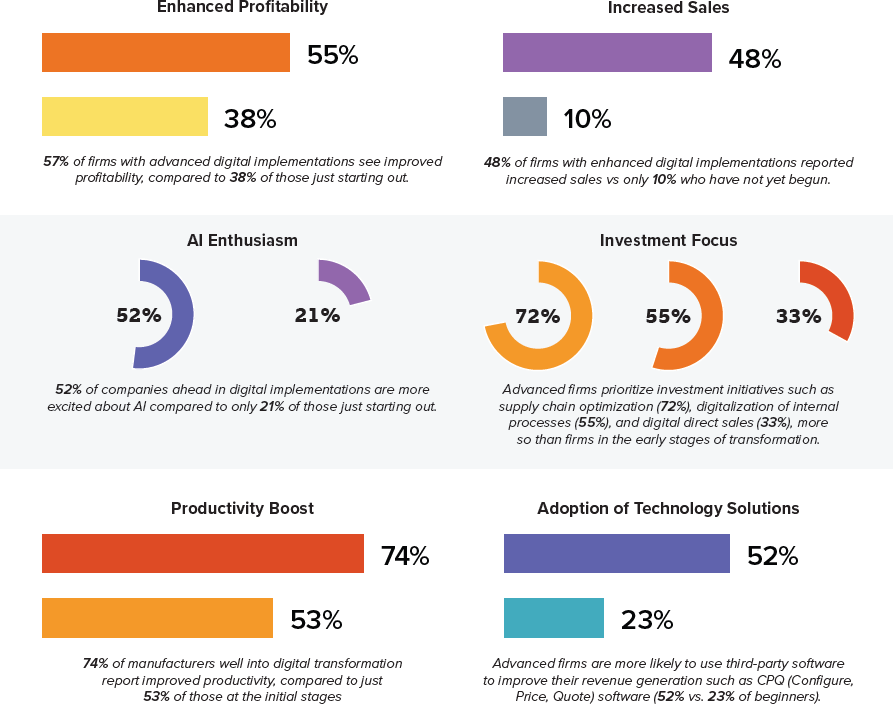

As part of our annual survey, we asked manufacturers about Digital Transformation efforts, 2024 Priorities and Sustainability. In addition to that, we also analyzed how the maturity of digital implementations impacts several areas of their business such as revenue generation, profitability & productivity. Our findings clearly indicate that manufacturers who are advanced in their digital transformation projects realize much more value than those who haven’t planned or are just starting out. Let’s review our key findings in this area:

Digital Transformation: A Strategic Imperative

The tumultuous events of recent years—from the pandemic to market fluctuations—have underscored the need for agility and foresight in manufacturing. Digital transformation emerged not just as a buzzword but as a strategic imperative, offering a lifeline for those seeking to enhance efficiency, optimize resources, and fortify operations.

Our findings reveal a significant divide between manufacturers embracing digitalization and those hesitating on the sidelines. Advanced digital implementations correlate with enhanced profitability, increased sales, and improved productivity. Companies at the forefront prioritize investment initiatives such as supply chain optimization, digitalization of internal processes, and AI integration, reaping the rewards of innovation and forward thinking.

The Impact of Delaying Transformation

Delaying digital transformation can have significant consequences for manufacturers, as evidenced by the data highlighting the benefits of advanced digital implementations:

Enhanced Profitability: Advanced digital implementations correlate with improved profitability, with 57% of firms benefiting compared to 38% at early stages. Delaying transformation hinders process optimization, cost reduction, and revenue maximization, affecting the bottom line.

Increased Sales: Firms with advanced digital implementations see a notable increase in sales (48%), while those lagging report only 10% growth. Digital technologies drive sales by reaching new markets, streamlining processes, and enhancing customer experiences. Delaying transformation risks missing out on sales opportunities and falling behind competitors.

Productivity Boost: Manufacturers in advanced digital stages experienced improved productivity (74%) compared to those at initial stages (53%). Digital tools automate tasks, optimize workflows, and empower employees, enhancing efficiency. Delaying transformation reduces productivity gains and hampers agility in meeting market demands.

However, delaying digital transformation comes at a cost. Laggards risk falling behind in a competitive landscape shaped by rapid technological advancements. With each passing day, the gap widens between those harnessing the power of digital tools and those clinging to outdated practices. Enhanced profitability, increased sales, and productivity gains remain elusive for those resistant to change.

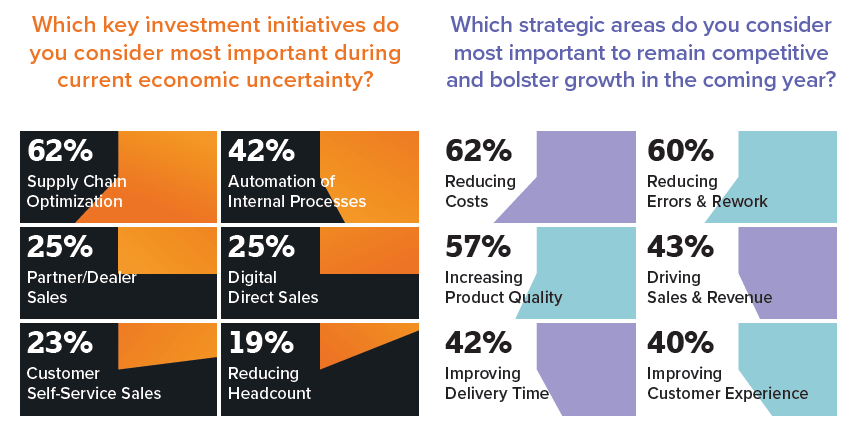

Priorities in a Shifting Landscape

As the economic outlook fluctuates, manufacturers face critical decisions about where to allocate their resources. Reducing costs, minimizing errors, and enhancing product quality emerge as top priorities in navigating uncertain times. Supply chain optimization remains paramount, underscoring the importance of resilience and adaptability in an interconnected global market.

Reducing costs has remained the most important area for manufacturers to bolster growth in 2024. This can be attributed to companies trying to maximize profit and reduce risk with the possibility of an uncertain economy.

Reducing errors and rework is vital for manufacturers as it directly impacts financial efficiency, product quality, and brand reputation, these are just a few reasons why there was a 13% increase in these initiatives since last year. Minimizing mistakes not only cuts additional costs but also ensures consistent high-quality products, enhancing customer satisfaction and safeguarding the company’s image

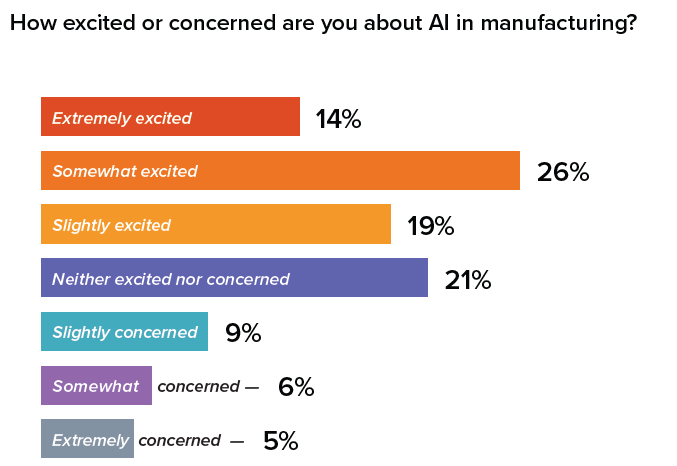

Artificial Intelligence

59% of our survey respondents are showing some level of excitement for AI in their manufacturing process. This group views AI as a catalyst for unprecedented innovation, efficiency, and competitiveness. They foresee a future where intelligent machines optimize processes, enhance productivity, and contribute to the development of cutting-edge products.

Delaying digital transformation, especially in adopting AI, can severely impact manufacturers:

Competitive Gap: Companies advanced in digitalization are much more excited about AI (52%) than those just starting out (21%). This indicates a significant competitive disadvantage for laggards, as AI drives insights, efficiency, and personalized experiences crucial for sales success.

Sustainability: A Cornerstone of Success

In an era defined by environmental consciousness and regulatory scrutiny, sustainability takes center stage. Manufacturers recognize the intrinsic link between sustainability initiatives and long-term success. Embracing sustainable practices not only meets consumer demands but also drives innovation, fosters resilience, and enhances brand reputation.

Manufacturers are increasingly propelled towards sustainability by a two-fold force: 61% respond to the demands of environmentally conscious consumers seeking products with minimal environmental impact.

Simultaneously, 44% are driven by a shifting regulatory landscape, including initiatives like the EU Green New Deal and the SEC climate disclosure Rule. These regulations set higher standards, compelling manufacturers to adopt sustainable practices not just for compliance but as a strategic necessity.

Looking Ahead with Tacton

As manufacturers embark on the journey ahead, Tacton stands as a trusted partner, empowering businesses to navigate complexities and seize opportunities. With our industry-leading CPQ solution, manufacturers can efficiently manage product variations, meet dynamic customer expectations, and thrive in the competitive landscape of 2024 and beyond.

In conclusion, “The State of Digital Manufacturing 2024” offers a roadmap for manufacturers navigating an era of unprecedented change. By embracing digital transformation, prioritizing sustainability, and leveraging innovative solutions, businesses can chart a course towards resilience, growth, and success in the years to come.

![Unlock Your Data with CPQ Analytics Software [Tech with Tacton]](/wp-content/uploads/2023/06/iStock-1098410490.jpg)