Advantages of CAD in Design and Presentation | Tacton

Discover the benefits of CAD & how it can improve your designs and increase productivity. Learn more about CAD advantages today. ✓ Learn more here.

The Advantages of CAD: Transform Design Plans into Digital Representations

Computer-aided design (CAD) burst onto the scene in 1957 and has been making waves and pushing the manufacturing industry forward for more than 25 years. The importance of CAD lies in the fact that it has revolutionized how people design structures and products, resulting in increased precision, versatility, and productivity in sectors all across the industry.

While many of today’s product engineers may take CAD for granted, it remains one of the most important developments of this era. Read on to learn more about what CAD software is, its pros and cons in manufacturing, and how you can pair this technology with CPQ to create even more effective systems and processes.

What Is CAD Software?

CAD is short for computer-aided design. Used in many industries, from software development to architecture, CAD is all about getting computer assistance to create designs and plans as quickly and accurately as possible.

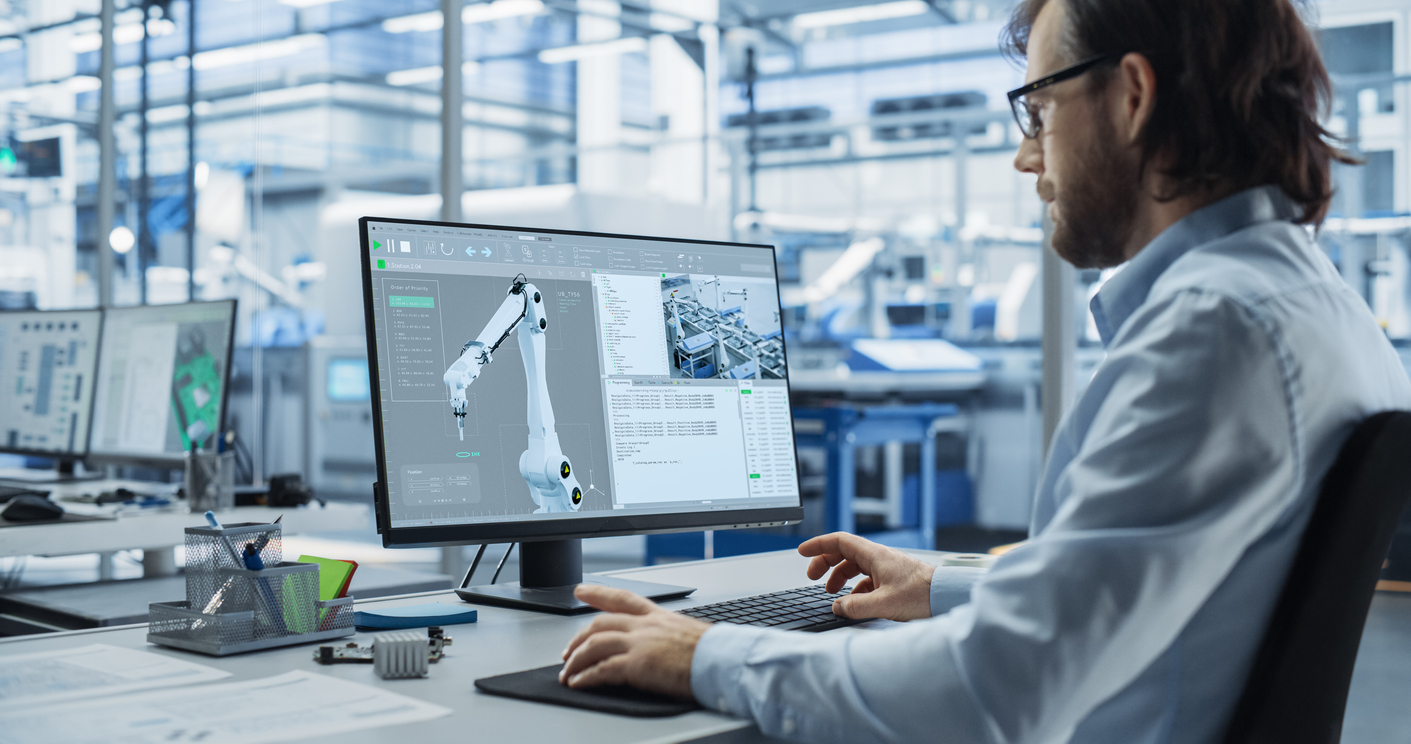

With CAD software, users navigate a graphical user interface (GUI) to make a two- or three-dimensional digital representation of a future (or existing) physical item. The software allows you to change your representation or modify existing elements before you make your model come to life in the real world.

How Is CAD Used in Manufacturing?

For decades, CAD technology has been a mainstay in the manufacturing industry, helping professionals design products and create photorealistic three-dimensional models that enhance accuracy and efficiency at every turn.

Still, CAD doesn’t just stop at realistic model creation. Instead of just understanding how the product will look, the software also allows you to simulate product functions to test dynamics, fluid flow, stress, and vibration. That enables you to spot errors and address issues before starting the manufacturing process.

CAD software truly shines in the post-model creation phase. Once the engineer has finished their 3D model, CAD allows those not skilled in using the software to manipulate the product. That is excellent news for executive and marketing teams who often need to keep tabs on product development but may need help understanding the nuts and bolts of product engineering.

As if these developments weren’t exciting enough, CAD takes the manufacturing process further by integrating with 3D printers to create product mock-ups. While these models won’t be as robust as the final product, they’ll be able to give teams and clients an idea of how it will look and feel, calibrating expectations and resulting in higher satisfaction with the end product.

The Advantages and Disadvantages of CAD for Manufacturers

There’s little doubt that CAD has been helpful for the manufacturing industry, as it can be used in many ways throughout the manufacturing process. However, CAD has both pros and cons.

Benefits of CAD

What are the advantages of CAD? Using CAD has a plethora of benefits for businesses in the manufacturing industry. Read on to discover how CAD improves the manufacturing process across the board.

Automation

CAD software is at the forefront of automation in the manufacturing industry. If your machinery can interpret schematic documents created with CAD, you’ll be able to create a speedier and more efficient production process, which ultimately helps reduce costs.

Efficiency

One of the most significant advantages of CAD is that it doesn’t just speed up the manufacturing process. It shortens the entire timeline from product design to deployment. Product designers can quickly create components for a product with built-in measuring tools and the ability to copy, paste, and resize without making an entirely new hand drawing.

Because the digital environment makes your processes so efficient, you’ll reap the benefits of outsourcing CAD translations and designs without hiring a third party.

Precision

The excellent news is that increasing automation and efficiency doesn’t mean designers and engineers must sacrifice accuracy. Using CAD software with all the available digital tools means an even greater level of precision than when designers create visuals by hand. Human error is significantly reduced, bridging the gap between the initial design schematic and the final product.

Visualization

The 3D visualization of all your designs is one of the most significant advantages of CAD software. Because you can see the product come to life, you can better evaluate it for any necessary changes.

One of the most practical applications of CAD customization includes allowing for more adjustments to be made in the design phase. That results in a better end product and lessens the need for expensive tweaks. This already-efficient process is further enhanced when manufacturing enterprises combine CAD with CPQ to let the customers design and modify their products.

Sharing

Only some people involved in the manufacturing process know how to use CAD software. These digital platforms allow designers and engineers to save their files in shareable formats so anyone can view them and understand their vision for the product. The whole team can give feedback on the design to ensure they’re all on the same page. That reduces disagreements and manufacturing issues down the line.

Disadvantages of CAD

While CAD has very few downsides, business owners need to know how to avoid the possible pitfalls of using this software.

Technology Breakdowns

Anyone who has used a computer knows they are prone to malfunctions. You can lose precious design work due to hardware malfunctions, viruses, or even hackers.

However, it’s important to note that this isn’t a reason to miss out on the advantages of CAD drawings. Instead, it should motivate those using the software to regularly monitor their system for potential threats or issues. This way, you can rest assured that your software will function properly and your designs will always be stored securely.

Budgetary Considerations

New CAD systems will require a significant upfront investment. Not only do you need to purchase the software and infrastructure, but you’ll also need to spend time and money training your employees to use it to its fullest potential. You’ll also have to stay on top of necessary software and operating system updates to maintain security and ensure continuous access to critical features.

Still, it’s important to note that although purchasing CAD software may require a budgetary investment, the return on that investment will make the move well worth it. Not only will it save you a great deal of time, but it also has the potential to impact your bottom line positively.

Pairing CAD and CPQ for Ultimate Efficiency

The advantages of CAD systems regarding the design and manufacturing process are clear. However, CAD benefits go far beyond this, especially when combined with other tools like CPQ.

CPQ (Configure, Price, Quote) streamlines sales processes. The buying journey doesn’t start with payment or product delivery — it begins with design. Pairing CPQ with CAD allows your business to avoid costly quoting errors that slow down productivity, removing manual steps and replacing them with automation you need to thrive in the era of customer-centered mass customization manufacturing.

Using CPQ and CAD, customers can use a self-service 3D visualization platform to customize their products in real-time and get immediate and accurate pricing for their configured model based on your set pricing criteria. Auto-delivered shop-floor-ready documents facilitate a smooth and quick transition from sales to manufacturing, all with customer satisfaction as the ultimate goal.

Get the Right Tools for a Successful Business with Tacton

Using CAD technology is all about utilizing automation and visualization to their fullest potential to create efficiency and precision in manufacturing. The good news? The same can be said of our CPQ platform. When pairing the advantages of cad, it can simplify and elevate your entire customer journey from the excitement of custom creation to the delight of timely delivery.

With Tacton Systems’ CPQ software, your enterprise will save time and money. Plus, your sales and engineering teams will have the tools they need to thrive, and your customers will be happy with quick turnaround on their custom-configured products.

Contact us today to learn how our CPQ solution can take your manufacturing business to the next level.